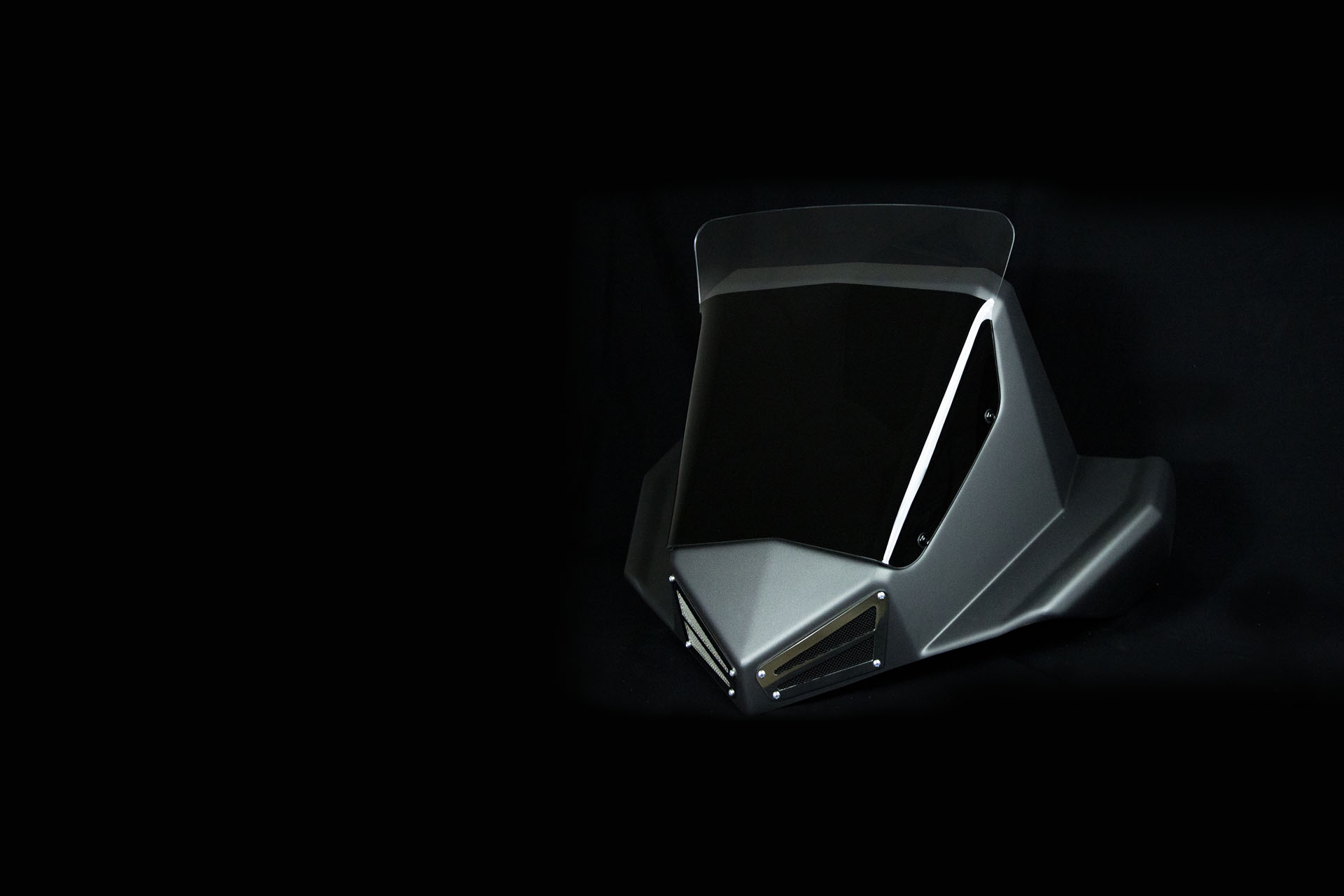

World class plastic thermoforming services

Reliable, expert, and competitive is what our aerospace, industrial, and marine OEM customers have come to expect from us. Fiber Pad leverages over 40 years of experience offering a comprehensive list of integrated manufacturing services to make your thermoforming projects move forward faster towards completion, and delivery, with the highest standards of quality and execution every step of the way.

Thermoforming

Fiber Pad offers a wide range of thermoforming capabilities for your specific needs. Click below to learn more about the different types of thermoforming options we offer.

In House Tooling

In house tooling capability design and manufacturing for quicker turnaround times. Click below to learn more about our tooling program.

Capacity

Running multiple shifts and machine redundancy to get the job done. Click below to learn more about our equipment mix and facilities.

Assemblies

We offer a wide range of assembly solutions to make turn-key parts, next level assemblies, or drop in bolt-on solutions. Click below for a list of our turn key services.

Metal to Plastic Conversions

Thinking about converting away from metal, fiberglass or injection molded plastic? Here is a list of advantages thermoforming can provide to make your conversion a success:

Compared to injection molding, thermoforming:

Has less expensive tooling costs

Faster tool changes

Can satisfy a lower volume niche & higher product runs

Produces a thinner gage than injection, resulting in lighter parts

Yields strong material from the uniform nature of the sheet versus random flow during injection

Compared to aluminum, thermoforming:

Has less expensive material costs

Creates lighter weight pieces

Makes parts more flexible and impact resistant

Is non-oxidizing and chemical resistant

Economically offers multiple cosmetic finishes

Has a wide variety of colors available

Compared to fiberglass, thermoforming:

Creates lighter weight and more durable parts (less cracking)

Offers better repeatability in each part, with less ambient influence on the process

Makes trimming into desired shapes easier

Offers solvent & ultra sonic welds

Produces less hazardous dust and raw materials

Creates no VOC’s

Is recyclable

Offers varied surface finishes and color throughout the part

Specialized thermoforming

Some of the world’s most recognized OEM’s rely on Fiber Pad for highly specialized thermoforming solutions.

Twin Sheet Process

Two plastic sheets are simultaneously heated and then formed or fused together to resemble a blow-molded or rotational molded product, with several advantages: two-color, two-material thicknesses option, hollow product, increased structural integrity.

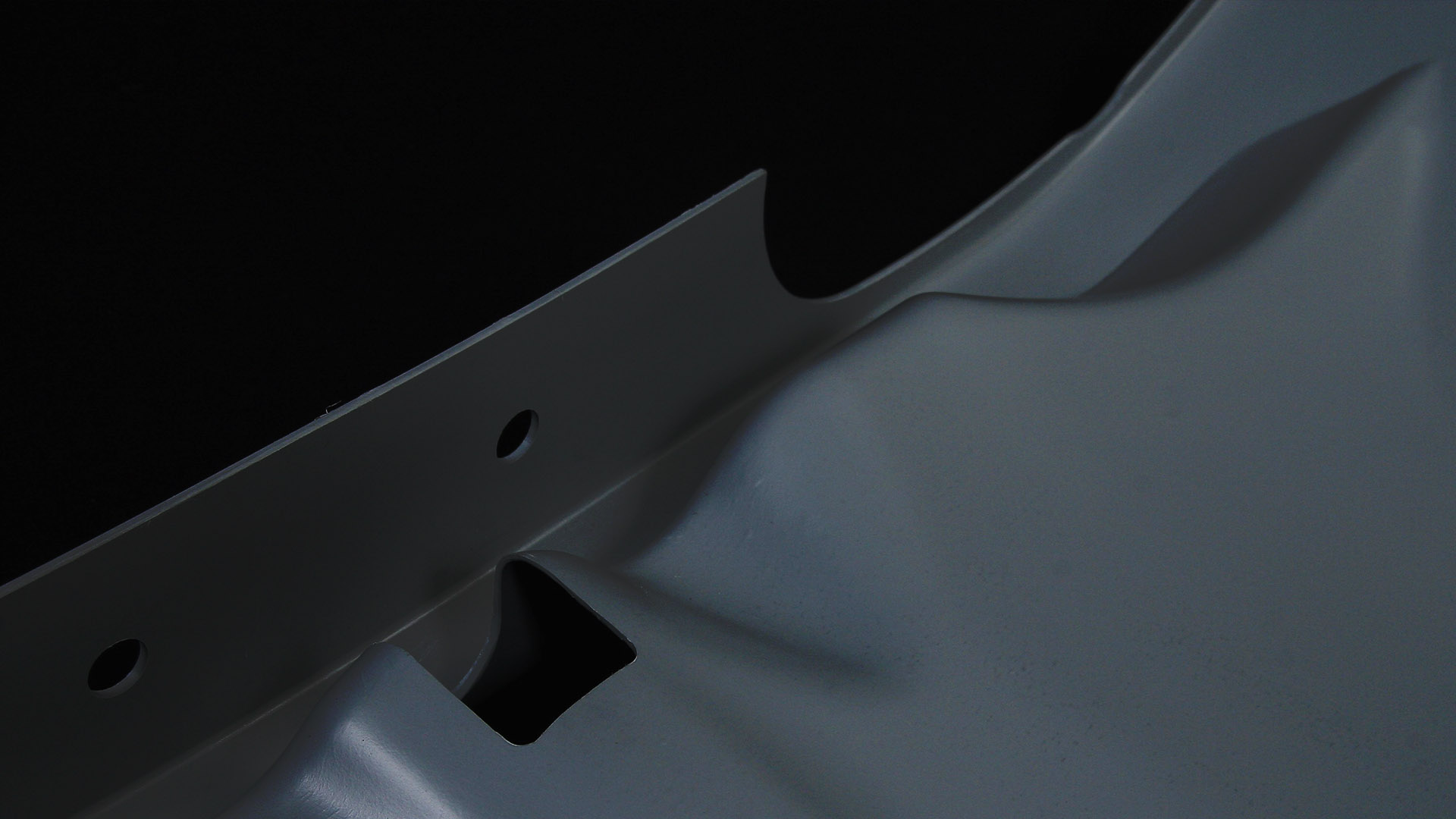

Undercut Process

Undercutting allows the plastic to form into an area of negative draft. Typically this means that it is difficult to release the mold from the plastic. However, Fiber Pad has specially designed machines and processes to enable designs with undercuts.

Pressure Forming Process

Vacuum and positive air pressure is applied to achieve injection-molded level of details and textures without the high injection molding tooling cost.

Our Industry Applications

Fiber Pad creates high quality parts that are built to AS9100 Rev. D & ISO 9001:2015 quality certification standards.

We have the expertise and machinery to create custom pieces unique to a wide variety of applications.

Aerospace

Aviation

Construction

Machinery

Energy

Fitness

Industrial

Marine

Medical

Recreational

Vehicles

Automotive

Aftermarket

Consistently Exceeding Expectations

Here is what we hear from our customers: